Stephen Hardy

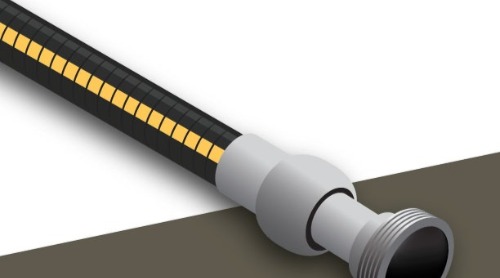

Rotary and Vibrator hoses are in high demand, but also at a higher cost rate. In order to prevent potential hose failures, these hoses must be maintained. Our number one priority is always safety, especially with these types of hoses. Vibrator and Rotary hoses are seeing up to 7500PSI working pressure, at this level of PSI, without proper maintenance, could lead to unnecessary catastrophic injuries.