Hydraulic fluid contamination with moisture and particulates causes 75% of all hydraulic component failures. Our dehydrator filtration cleans your hydraulic fluid to achieve particle counts as low as ISO 14/12/9; increasing productivity, minimizing downtime, and preventing premature fluid replacement.

Not only does it clean oil, but it removes water (dissolved, emulsified and free), gases and solid contaminants so the oil can return to its ISO count. Having clean, dry oil will allow hydraulic systems to perform more efficiently and can result in significant FINANCIAL GAINS.

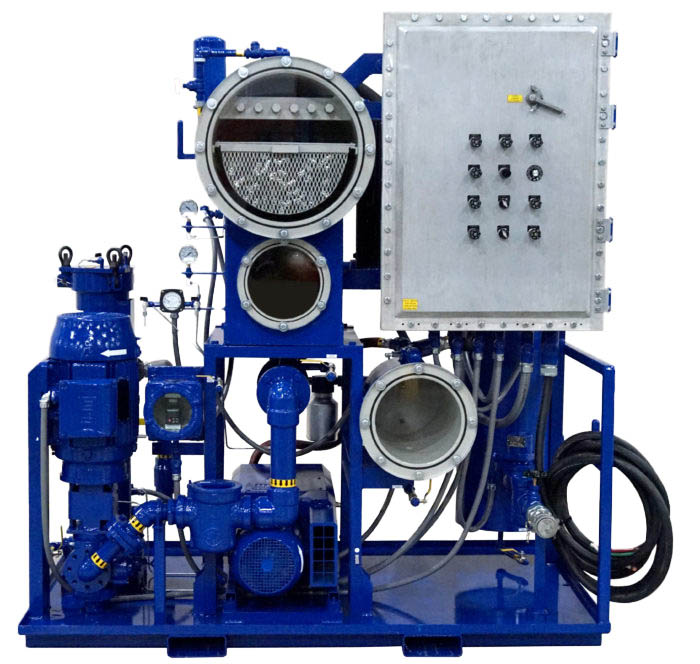

The Vacuum Dehydration Units can remove 100% of free and emulsified water and up to 90% of dissolved water from industrial oils. It can also remove 100% of free gases and up to 90% of dissolved gases, and removes free and dissolved water down to 20 PPM.

Our techs have the technology to analyze fluid and give ISO counts and water saturation levels within minutes. No more mailing samples and waiting for results, with Austin you get results instantly. Data collected is always emailed and saved with work-orders.

Our mobile unit has an on-board power supply for remote location jobs or on-site locations without power.

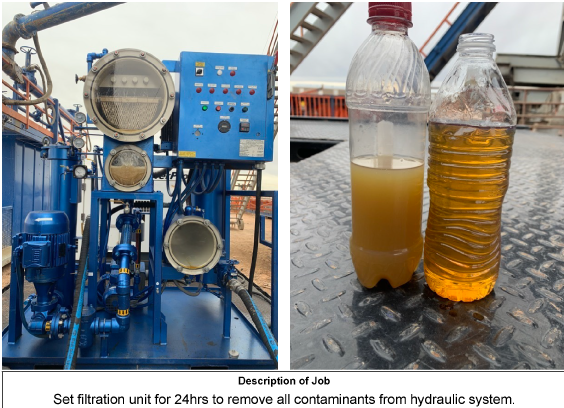

When we do an oil filtration job there is zero downtime on YOUR equipment, we plug-in to the system as it’s still in operation. We typically run our units 24hrs depending on oil contamination and reservoir tank sizes.

· Drilling rig HPU’s

· Top Drive HPU’s

· BOP systems with heavy water saturations

· Coil Tubing HPU’s

· Frac equipment

· Heavy equipment machinery

· Blender units

· Wind Turbine HPU’s

· Tractor WetKits

· Pipe yard HPU’s

· Triplex and Quintuplex gear oil

• Allows oil to heat quickly thus removing water faster

• Real-time water content indication in % saturation

• Unattended use, reducing labor costs, set it, and

forget it

• Designed for 24 hr operation

• Able to view the vacuum dehydration process, providing visual verification of water removal

• Desiccant breather ensures dry, clean intake air, providing more efficient operation

• Flexibility with various fluid viscosities, providing greater efficiency in removing moisture